Introduction

This is a site about how best to build large-span roofs.

Looking at some of the existing large-span structures - e.g. on

http://largedomes.com/largest/

it appears that quite a large number of different approaches have

previously been employed to achieve large-spans.

The largest-span enclosed space in the world is in Oita,

Japan - the dome there has a diameter of 245 metres.

Bridges

However this figure doesn't look so significant when it is

compared to what bridge builders - the world's experts at

constructing large spans structure - can produce.

In the world of bridges, suspension bridges produce

all the largest spans in the world.

In terms of their potential for spanning large distances,

bridge designs stack up against each other something like

this:

- Suspension bridge: the largest spans 1989 metres;

- Cable-stayed bridge: the largest spans 890 metres;

- Arch bridge: the largest spans 550 metres;

- Cantilever bridge: the largest spans 549 metres;

To illustrate these approaches:

Suspension bridge

|

Cable-stayed bridge

|

Arch bridge

|

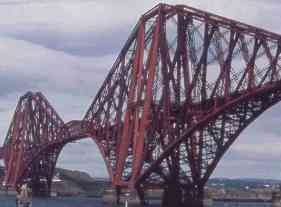

Cantilever bridge

|

Looking at the largest large-span arenas in the world, none

of them use the catenary suspension technology used in

suspension bridges.

A few use cable-stay technology - the largest of

which are the Muna Bulk Reservoir Cover (210 metres), and

The Millennium Dome (206 metres), and the Cardiff Millennium

Stadium (181 metres).

What type of technology do the domes use? There is

some variation - but here are some of the most common

principles:

Arches

The principle of an arch is the principle on which the five

largest span domes in the world are constructed on.

The principle of an arch is the principle on which the five

largest span domes in the world are constructed on.

From the perspective of large-span bridges, using an arch is

not normally regarded as being very sensible. The largest

arch in the world is the Lupu Bridge. This spans 550 metres

- much smaller than cable-stayed bridges and

much much smaller than catenary-

suspension bridges.

The reason arches are so poor at spanning large distances

boils down to weight. Struts in compression have to be fat

and heavy to avoid buckling - and the effect accumulates -

if you make something in the middle of a bridge fat and

heavy the stresses on the components on either side are

increased - so they need to be fatter and heavier too.

So: why are dome builders still using this technology for

creating large spans? I have yet to hear a satisfying

reason given in answer to this question.

Aspension

Another technology used by the dome builders that begins

to take advantage of the tensile properties of materials is

represented by structures such as the Tropicana field. This

is distributes struts along the length of the span - rather

than piling them up at each end as a suspension bridge does.

Another technology used by the dome builders that begins

to take advantage of the tensile properties of materials is

represented by structures such as the Tropicana field. This

is distributes struts along the length of the span - rather

than piling them up at each end as a suspension bridge does.

I will refer to this type of design as an "aspension"

structure - following the terminology of Buckminster Fuller,

who - as far as I can see - came up with the idea originally.

It is challenging to compare real aspension bridges to

suspension bridges - because no aspension bridges have

actually been constructed.

However, probably the main reason no aspension bridges have

been constructed is because the idea doesn't make much

sense.

Why would a designer distribute their compression members

along the bridge - where their weight has to be supported by

the cables - when they can pile them up at each end on solid

land - taking advantage of cheap-but-heavy materials such as

reinforced concrete - and in the process wind up with a

bridge which is much stronger - due to being anchored to

points far from the roadway?

Air support

The next most common type of dome technology is the

air-supported dome.

The next most common type of dome technology is the

air-supported dome.

However, no large air-supported structures

have been constructed for decades.

The technology fell out of fashion - around the time when

aspension structures came into vogue.

Air-supported structures have some problems associated with

the inconvenience of maintaing internal pressure - and can

suffer from occasional deflations.

Suspension technology

The thesis of this site is that stadium constructors - and

other makers of large-span enclosures - would be well

advised to take a leaf out of the bridge builder's book -

and start making more use of suspension bridge technology

and cable-stayed structures.

For more details, go on to the

"why suspend" page.